Where the name "pasta filata" comes from

Pasta Filata is not just any type of cheese. Cheeses that can proudly bear this name must fulfil special criteria. Formaggio a Pasta Filata roughly translates as "cheese with spun dough". And this name is no coincidence: the production methods used to make pasta filata make it stand out from the crowd. Pulling, stirring and kneading are an integral part of the process of creating this cheese speciality. Pasta filata also belongs to the so-called scalded cheeses. This is due to the characteristic scalding of the cheese after acidification.

Interesting facts about provolone

Provolone is one of the lesser-known cheese specialties. You will search in vain for its name in the numerous popularity rankings. Provolone - or Provola - is a pasta filata cheese speciality that enjoys a designation of origin. Several northern Italian provinces are among the authorised production areas for Provolone. A special feature that distinguishes it from the other pasta filata cheese specialties is the maturing time. While mozzarella only has to mature for a very short time or not at all, provolone cheese is matured for 15 days to 12 months. Compared to mozzarella, provolone has a firmer paste with a white and light yellow colour.

Extremely popular Italian

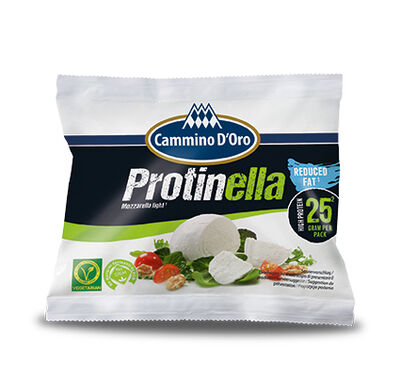

Mozzarella is probably the best-known representative of the pasta filatacheese specialties. The whole world loves the Italian cheese, which is available on the cheese market in a wide variety of forms. As a small mini mozzarella, such as our popular GOLDSTEIG Bambini, in the well-known mozzarella ball or as practical, firm slices. Mozzarella is so popular because it has an individual flavour that is unrivalled in the world of cheese. It is characterised by its creamy, mild taste, in which the milk can still be clearly felt on the tongue.

Stirring, kneading, pulling

The purified and flash-heated raw milk is heated to 32 - 33 degrees Celsius and adjusted to a pH value of 5.90 with citric acid. The milk, thickened by adding rennet, is cut into small cubes using a cheese harp. The resulting mixture of curd and whey is then separated using a sieve. The curd mass itself is again cut into small pieces in a filing machine and doused with water heated to 80 degrees Celsius. The hot mixture is then stirred, kneaded and, of course, pulled (filare = to pull). The aim of this filleting process is to create an elastic, mouldable and soft dough with the chicken-like structure typical of mozzarella. This dough is moulded in various sizes, cooled and packed in a tubular bag with brine and made available to the consumer in stores.